Airnergy Sdn Bhd

18, Jalan Anggerik, Mokara 31/46, Kota Kemuning, Seksyen 31, 40460 Shah Alam, Selangor, Malaysia.

+603-5892 2948

+6012-748 8163

+6012-566 8163

+6012-748 8163

+6012-566 8163

+603-5892 2948

Payment & Billing

+60125668163Payment & Billing

Timer Auto Drain Valve BK-DP-B

| Previous | 6 / 20 | Next |

Features

Description

Description

Electronic drain valves are widely used in air compressor, cooler, separator, dryer, filter, gas tank…etc. compressed air system components, discharge time and internal time can be adjusted.

Condensate drain valves remove condensate from the air system without losing excessive compressed air and without shutting down the system. Condensate can have harmful effects on a system when not removed. For instance, moisture can wash lubrication from air tools and production equipment causing downtime and maintenance; an inconsistent supply of dry air can cause production quality problems; and excessive rust and scale can form in the air distribution system. Also, water can back up into the compressor and wreck the machinery, air dryers can become overloaded, and in-line filters can be destroyed.

Instruction

Instruction

How to set Timer:

Left – button to set the discharge time, the right knob to set the interval time; emission time 0-10 seconds, the interval time is 0-45 minutes.

How to clean valve core:

(1) to close the isolation valve, press the TEST key to empty the compressed air, to ensure that the drain valve has been isolated from the air pressure system (zero pressure).

(2) cut off the power supply of the drain valve

(3) remove the coil (before, remove the coil electronic drain valve must be off, otherwise coils in from the stem after burned), unscrew the six hexagon nut, remove the spool and valve seat, valve spring cleaning, and spring and the valve core sheath, re installed.

Exception handling:

(1) electronic drain valve is normal, but no water rule out, it is likely that the filter screen is blocked, then need to clean the filter, filter at least once a month

(2) in case of damage, the solenoid valve does not close (flat), which may be due to a large number of condensed water powder into the screen, enter the gap between core and sheath, will spool stuck, then need cleaning valve

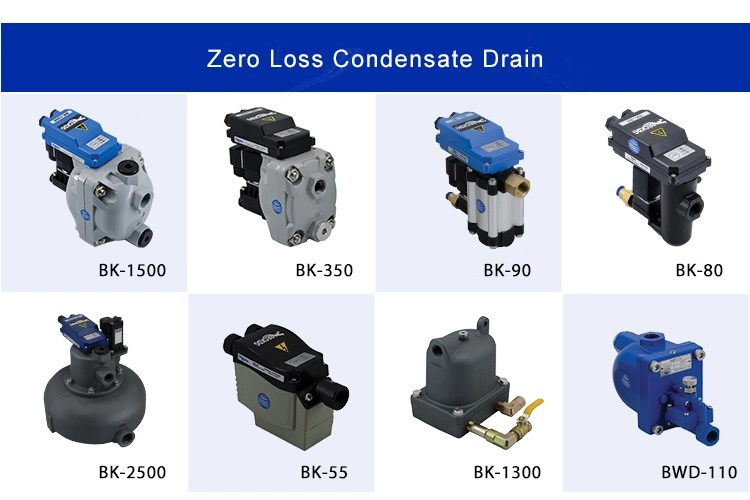

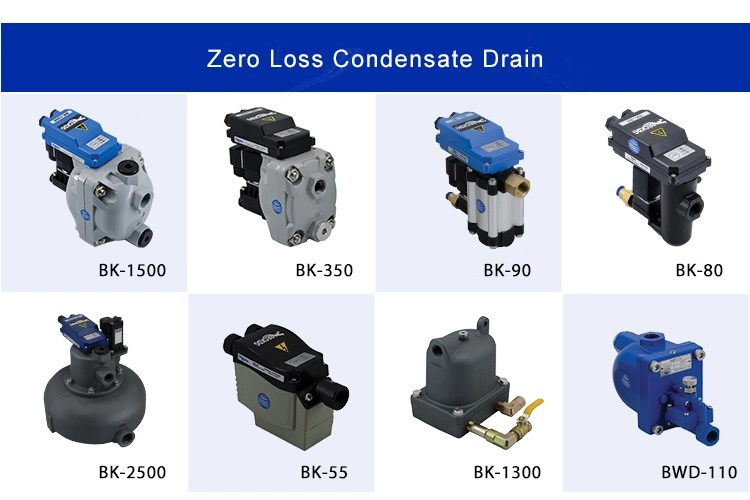

More Products

More Products